PROCESS MAPPING – Improvement Engineer & Consultant Services

We Help Manufacturing Companies: Process Mapping Improve Production Productivity Quality – Cost Savings and Process Improvement Services

.

We Offer Process Improvement & Cost Reduction

.

Process Mapping:

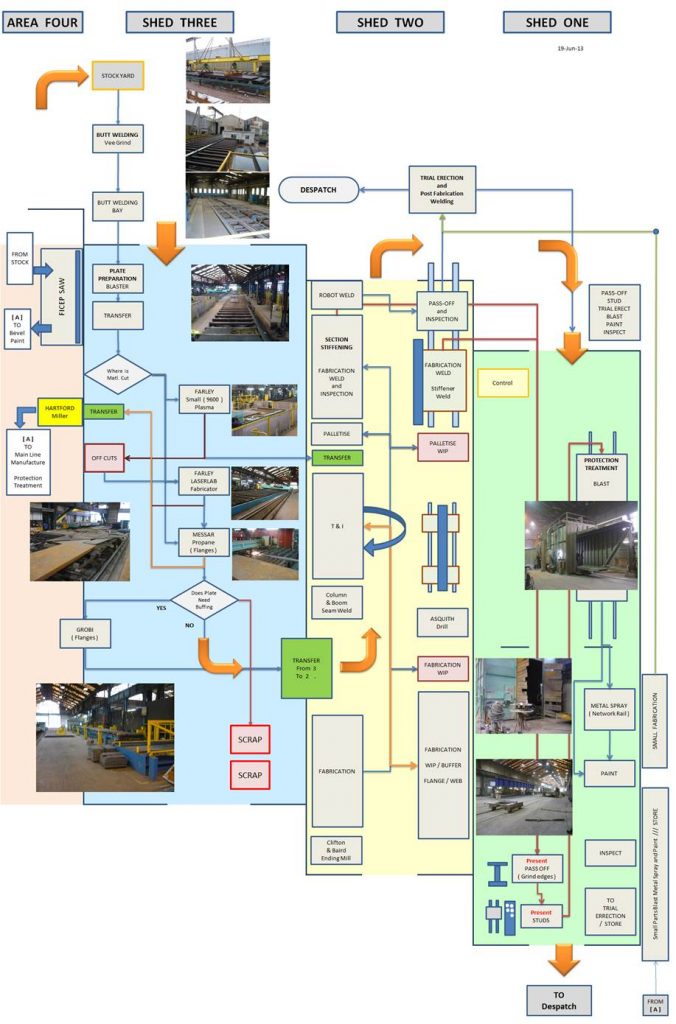

Process Mapping:- Is finding out what is happening within your business… Who Does What – When – Where – How – ‘What Are You NOT Doing’…

Value Stream Mapping:- Is a method of visually mapping the “flow of work”, materials and information. 1. To highlight “Time” & Non-Value waste activities 2. To find the ‘Value Stream‘… 3. To Remove Non-Value Waste.

Process Mapping or Value Stream Mapping; can be applied to an office, service or manufacturing, the basic principles and analysis are the same…

.

Services We Offer:

.

The First Step:- Document the ‘Present State’ – Without knowing the present state, REAL improvements will not be found or solutions implemented…

We look for “Non-Value Waste”.

- Waste in Time – Inventory –

- Movement – Waiting –

- Over-processing –

- Rejects – Scrap –

- Machine down-time.

We Give Hands-On-Help:-

- We Identify Opportunities –

- Measure Present State Situation –

- Analyse and Develop Solutions –

- Implement Sustainable Change…

If you don’t have the information – you don’t have control of the business. This will result in the business losing money.

.

Process Improvement + Non-Value Reduction = Business Cost Reductions

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail