LEAN INDUSTRIAL ENGINEERS – Engineer & Consultant Services

We Help People In Manufacturing Improve Process and Productivity – Reduce Business Costs – We Are Time & Motion Study LEAN Industrial Engineering Consultants

.

Business Support For The UK Manufacturing Industry:-

.

We Are LEAN Industrial Engineers and Manufacturing Improvement Engineers.

We.help.people.in.business.improve their business and reduce costs.

- We design and organise factories to improve processes.

- We find, drive and implement process improvements.

- We implement improvements to increase profits.

- We turn opportunity into fact …

.

Innovation is the process of making ‘change’ that adds value…

We look beyond the obvious to find innovative solutions…

- To Reduce Non-Value Waste

- To Reduce Machine Down-time

- To Improve Process, Productivity, Profits

- To Improve Quality and Customer Satisfaction

.

& Plant Organisation

We Can Help You With:

- Factory Organisation

- Warehouse Organisation

- Lean Process Improvement

- Time and Motion Study Analysis

- Write Work and Quality Procedures

.

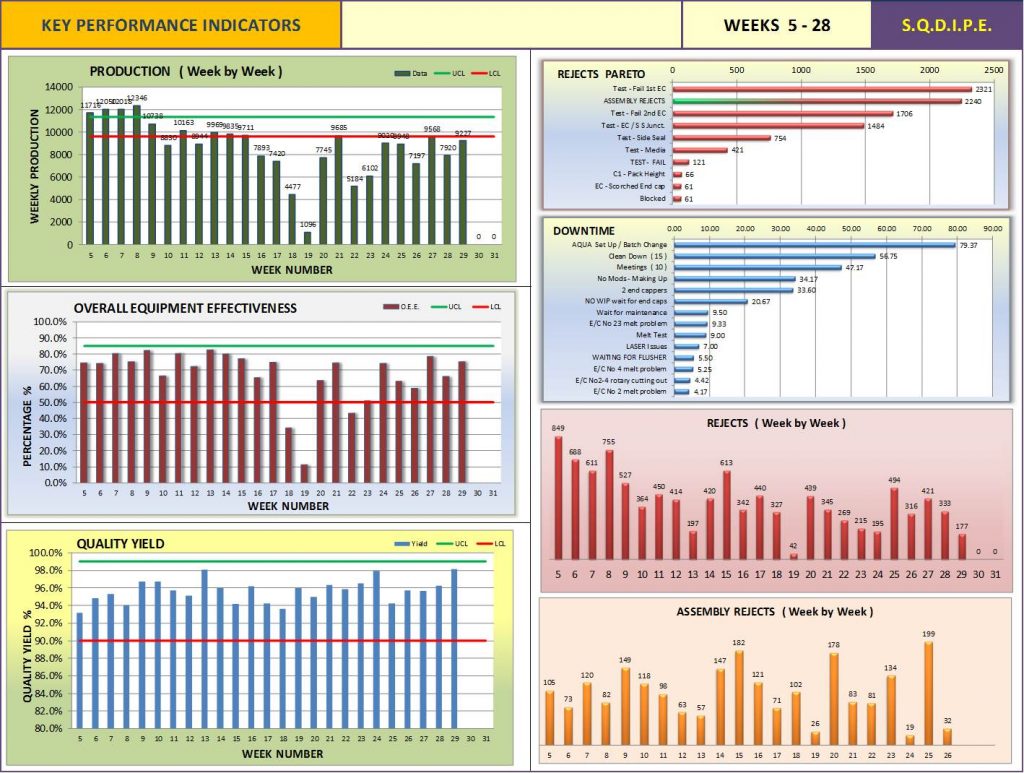

Key Performance Indicators

Business Support:

- Improve KPIs, OEE

- Reduce Scrap Levels

- Improve Product Quality

- Improve Process & Efficiency

- Improve Cash Flow, Sales and Profits

.

.

Services We Offer:

.

Industrial Engineers and Industrial Engineering UK:

Industrial Engineering is the development, improvement, implementation of processes and reduction of costs

- Industrial Engineers are PROBLEM SOLVERS – Specialists in LEAN process and productivity improvement.

- IE; Deals with Factory Layouts – Process Methods – Product Build Time – Product Quality – Tooling Issues – Machine Down Time – Scrap and Rejects – Materials Organisation – Manning Levels – Written Procedures – Energy Management – Analysis and Synthetics of Production Data..

.

Process Mapping and Value Stream Mapping:

We can help you to find out how efficient and productive your people are:- Who does What – When – Where – How – How long is a job taking – How much time is Non-Value. Find Out What Is Your Business Value Stream Is.

.

Visual Management Controls / KPIs:

We can help you find out:- What is happening within your business:- Production Numbers – Quality Issues – Rejects – Machine Breakdowns and much more.

.

Work Study and Method Study:

We can help you implement “Best Practice Methods” to improve process, productivity and profits.

.

Cycle Time Measurement:

We can help you establish a “STANDARD TIME” for an operator to carry out a job.

.

Factory Floor Layout Design:

We can help you create a LEAN factory layout that will improve production flow.

.

Warehouse and Inventory Organisation:

We can help you with a LEAN Warehouse. Kitting area, Supermarket, Kanbans.

.

Machine Breakdown – Stoppage Analysis:

We can help you to analyse machine downtime, rejects, scrap. Implement TPM.

.

Standardised Work Process Procedures – SOP’s:

- Standard Operation Procedures – to improve operator performance and quality.

- Planned Maintenance Procedures – to improve up-time, production and productivity.

- Quality Standards – to improve operator awareness, skill levels and customer satisfaction.

We Help People Identify Opportunities to Improve Processes and Reduce Costs

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail