PROCESS PRODUCTIVITY – Improvement Engineer & Consultant

WE HELP Manufacturing Companies Improve Process, Productivity, Efficiency, Reduce Costs – Process Improvement Consultant Engineer 30+ yrs. ROI 13/1 ave.

.

HOW TO REDUCE COSTS by IMPROVING PROCESSES

.

Problems You May Have:

- Achieving Targets

- Work-flow Shortfalls

- Production Downtime

- Layouts Not Organised

- Not Hitting Client Enquiries

- Not Hitting Customer Delivery Dates

.

We.Can.Help.You.With:

- Workplace Layouts

- Time and Motion Study

- Activity Sampling Analysis

- Improve Process Efficiency

- Improve Machine Reliability

- Improve Value Stream Process

.

Edwards Deming said:-

Adopt The New Philosophy:

- Design products and services to meet customers’ needs.

- Put your customers’ needs first, rather than to competitive pressure.

- Look at how the process is carried out – Not just numerical targets.

- Provide support and resources so that production levels and quality are achievable.

- Create your “Quality Vision” and implement it – “Fit For Purpose” not cheap and nasty.

- KEEP IT SIMPLE – REDUCE VARIATION – INCREASE PRODUCTION – INCREASE SALES

Services We Offer:

.

Process Improvement Management:

We Can Help You: Reduce Your Costs and improve production by finding out how your business works…

- We are LEAN Industrial Engineers: Specialists in LEAN process and productivity improvement

STEP 1:- ASK QUESTIONS what problems and issues you have – what would you like to see change

STEP 2:- DEFINE & MEASURE the present issues, process value stream, quality and stoppages

STEP 3:- SORT THE PROBLEMS with Hands-On-Help. Then IMPLEMENT “SUSTAINABLE CHANGE”

STEP 4:- You BENEFIT FROM “CHANGE” Reduced Running Costs & Improved Production, Productivity, Profit

.

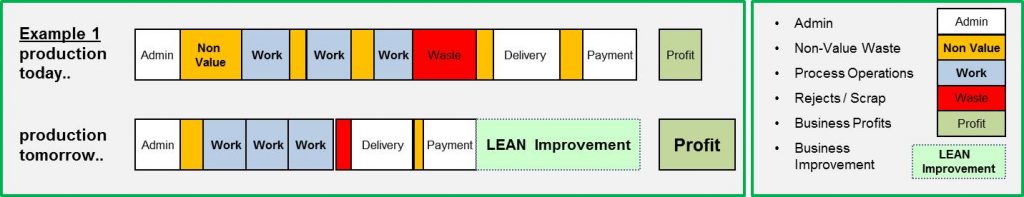

Lean Manufacturing Improvement Example in the Workplace

If You Improve Processes – You Reduce Costs – You Improve Profits and Cash Flow

.

IMPROVED PROCESS = REDUCED BUSINESS COSTS

We can help you improve processes and reduce costs

For one client we improved product work flow – Saved circa €500k

For one client we designed a new workplace layout – Saved circa €1.3M

.

We Help People Identify Opportunities to Improve Processes and Reduce Costs

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail