How To Design Manufacturing Plant Layout

How To Improve Process & Reduce Costs in the Manufacturing Business Workplace – Case Study Implemented

.

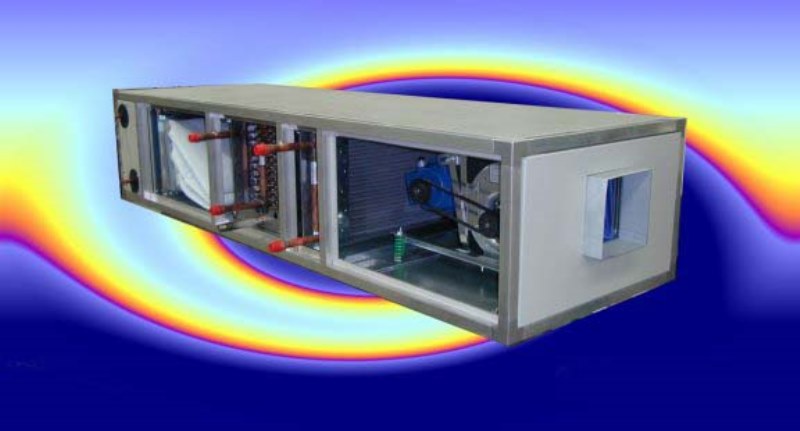

Case Study Implemented – HVAC Manufacturing Transformation

OBJECTIVES:- To reduce the NCRs by improving methods, quality and standardising product… RESULT:- Give them the competitive edge to increase business – Reduced costs circa £229k

.

PROJECT WORK DONE:

- Operator activity sampling

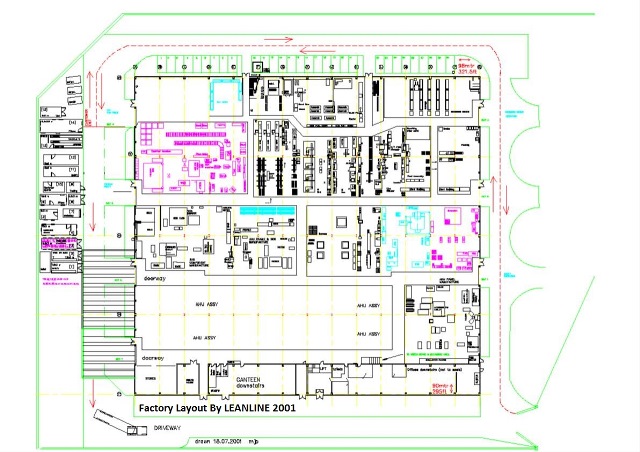

- Floor design and re-layout

- Standardise product range

- Time and Motion improvements

- Write a Standard Op Assembly Manual

- Implement new methods – reduce build costs

.

PROJECT RESULTS:

- £45,000 – Labour Time Savings

- £28,000 – Inventory Cost Reduction

- £64,000 – Material Scrap Reduction

- £88,000 – Customer Complaint Reduction

- £4,200 — Energy Management Reduction

FINANCIAL BENEFITS:

This Project Potential Savings Per Annum circa £229k

.

We Help People Identify Opportunities for Improving Business and Implement Change

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Return On Investment; Client savings compared against contractor costs. Recent average circa R.O.I. 13 / 1

Please Contact Us:- UK – 07300 788 486 – or by E-Mail…