LEAN MANUFACTURING – LEAN Engineer & Consultant Services

We Help Companies Improve Process, Productivity, Profits and How To Reduce Business Costs – Implementing Simple LEAN Manufacturing Principles

.

HOW TO ACHIEVE COST SAVINGS IN BUSINESS:

.

LEAN Manufacturing Engineering:– A methodology that when implemented will reduce costs – improve processes – improve quality and improve your financial bottom line profit.

.

LEAN MANUFACTURING PRINCIPLES:

- 1.Design In Quality: Design Simple Products and Process

- 2.Eliminate Non-Value Waste: Time – Movement – Travelling

- 3.Implement Quality Awareness: Training and Simple Procedures

- 4.Implement Total Planned Maintenance: And Reduce Energy Costs

- 5.Implement The Reduction Of Waste: Rejects, Scrap, Over Processing

- 6.Adopt “LEAN” Manufacturing Principles: To Improve Your Business

- 7.Adopt SIMPLE: Elimination of Mixed Materials In The Product Design

- 8.STANDARDISE: To Improve Production, Productivity, Cash, Profits

- 9.REDUCE VARIATION: To Improve Production, Sales, Profits

- 10.Adopt “7S” Principle: If you don’t use it SELL IT…

.

Services We Offer:

.

We Can Help You: find out what is happening within your business… Production Numbers – Quality Yield – OEE – SMED – Tooling Change-Overs – Machine Breakdowns and much more…

- We are Problem Solvers: We give hands-on-help – Identify opportunities – Measure Present State Problems – Analyse and Develop ideas – Implement Future State Sustainable Solutions…

- WE CAN HELP YOU REDUCE COSTS

.

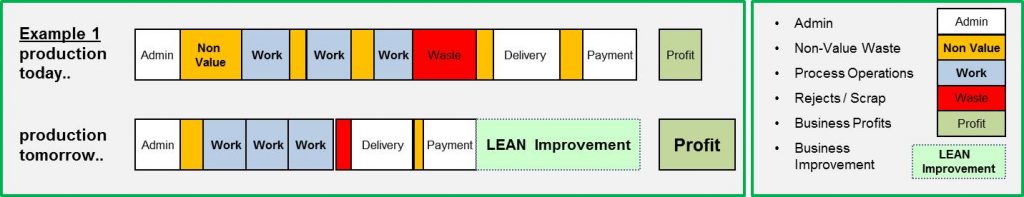

Lean Manufacturing Improvement Example in the Workplace

If You Improve Processes – You Reduce Costs – You Improve Profits and Cash Flow

.

We Help People Identify Opportunities to Improve Processes and Reduce Costs

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business

Please Contact Us:- UK – 07300 788 486 – or by E-Mail