How To Reduce Costs In Business & Food Industry Workplace

How To Improve Production, Process & Reduce Business Costs in the Food Industry – LEAN Manufacturing Case Study Analysis

.

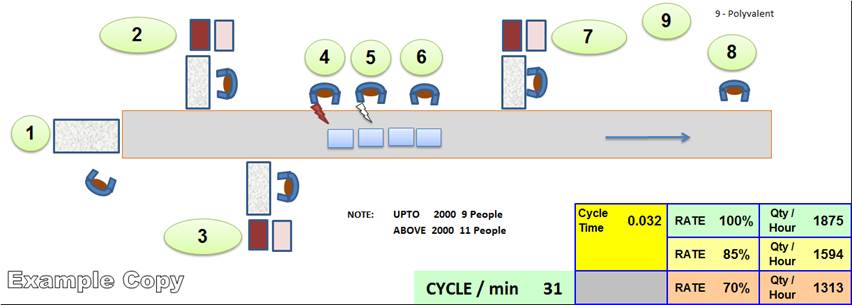

Case Study Analysis – Food Industry: Cream Cake Manufacture

OBJECTIVES:- To balance a single piece flow line by implementing time & study work and line-balancing RESULT:- Reduced manning level – improved production by circa 30%

The Project:- was undertaken to balance a food packaging line where the production line was not reaching targets… The line kept stopping and starting. Supervisions answer “put more people on the line” (which slowed the line down)

.

PROJECT WORK DONE:

- Time and Motion Study and LEAN Line Balancing

- Takt Time and Targets cementing the new improvements

- Standard Work Procedures cementing “Best Practice Methods”

.

PRODUCTION PACKING LINE – Previous State:

- Production lines are running 40hrs/wk – 52 wks/yr…

- The company running 3 production lines

- People per line = 12. ( total 36 people )

- Operators are working around 70% efficiency

- Lines producing around 1260 per hour ( total 3780 )

Also with the way the line is run much of the product ends up on the floor.

.

PRODUCTION PACKING LINE – Future State:

- Apply a Time and Motion Study

- Apply Flow-Line-Balancing Takt Times

- Lets now operate and run 4 production lines

- People per line = 8 + runner = 9 ( total 36 )

- Operators now working at around 90%

- Lines now producing 1800 per hour ( total 7200 )

.

FINANCIAL BENEFITS:

1. Production could be doubled ( from 3780 to 7200 ) at NO Extra Cost

2. This Project Could Realise An Extra Sales Value circa £2.0M per annum

3. Running of ONE Line – Manning reduced by 3 operators + 30% increase in production

.

Experience doesn’t just come from working in the food industry but from working in many different sectors…

.

We Help People Identify Opportunities for Improving Business and Implement Change

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please Contact Us, tell us your issues – tell us how you would like to improve your business.

Return On Investment; Client savings compared against contractor costs. Recent average circa R.O.I. 13 / 1

Please Contact Us:- UK – 07300 788 486 – or by E-Mail…