ATHERTON MANAGEMENT SERVICES LTD “LEANLINE”

We Help People In Manufacturing Improve Process and Productivity – Reduce Business Costs – Increase Profits, Cash Flow, Cash In Bank

.

LEAN PROCESS IMPROVEMENT ENGINEERING and CONSULTING

- We are a long established independent company: serving many different manufacturing industrial sectors. For over 30 years we’ve helped many companies improve their business and generated cash for them...

- Our portfolio encompasses: Aerospace – Automotive – Electronics – Food & Drink – Ink – Light Engineering – Heavy Engineering – Medical Devices – Moulding – Print – Pharmaceutical – Woodworking – White Goods – Warehousing – Sewing – UPVC – NHS etc…

- We have carried out projects and process improvements mainly in the UK but have also successfully managed projects internationally in Canada, France, Czech Republic, Ireland and The Netherlands…

- Our Industrial Engineering services: can help you develop and transform your business to improve process, productivity and help you reduce costs…

WE HELP PEOPLE IN BUSINESS – IMPROVE THEIR BUSINESS

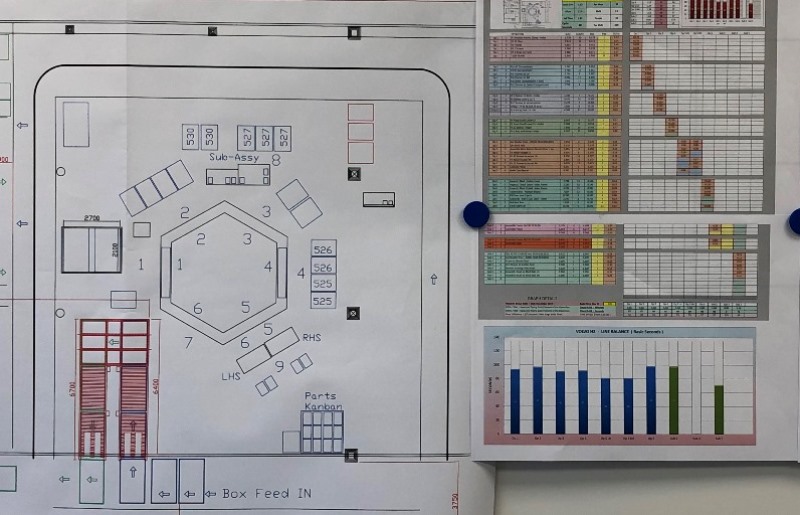

- Visual Management / Key Performance Indicators

- Process Mapping / Value Stream Mapping

- Work Study and Method Study

- Cycle Time Measurement

- Factory Floor Layout Design

- Machine Breakdown Analysis & TPM

- Write Standardised Work Process Procedures

- Workstation Design: Single-piece-flow – Line Balancing

- Workplace Organisation: Lean Process Design – Cell Design

- Warehouse Organisation: Inventory, Supermarket, Kitting, Kanban

- Energy Management To reduce Energy Waste – Help in the Race Towards ZERO

- Methodologies: Lean – Six Sigma – 7S – KPI – SPC – OEE – SMED – TPM – DFA – DFM – MTM – WCM

Over the years we’ve generated for our clients £50k to £2.0M per project… Return On Investment 13/1

.

Just a few of our many projects throughout the years.

2020 – 2025

In 2025: Asked to help a company draw present factory layout – process map office procedures & shop-floor process Improve production and productivity to reduce costs and improve profit

In 2023: We were asked to help a company with a new factory layout – time & motion study work – write procedures.

In 2021: We were invited to help a company organise their warehouse and distribution centre to improve their logistics.

2010 – 2019

In 2018: Netherlands: A global manufacturer planned to increase production of one of their products from circa 60,000 per year to circa 90,000 per year in 2020… Project Focus:- manning levels, material logistics, tooling needs, layout, build time. Results Achieved:- single-piece-flow – Kanban – manning balanced, the numbers

- 1.Time and Motion Study: Elements of the assembly timed by stopwatch.

- 2.Workplace layout: Designed for minimum movement reducing Non-Value.

- 3.Line balancing: To achieve production requirement for 2020 circa 90,000.

- 4.Material feed: A Supermarket and Kanban created. Materials available 24/7.

- 5.Manning: This was organised as to production requirement. (9 + 1 polyvalent).

- 6.Quality: “Every operator is responsible for his/her own quality” Training and quality awareness introduced.

.

In 2015: Northamptonshire: The company, a global manufacturer of blow moulding containers felt that a Continuous Improvement opportunity could improve their manufacturing, production output and increase their business profits.

- 1.Time and Motion Study: Highlighted where improvements could be made.

- 2.Machine Cells: Re-engineered and new cell layouts were implemented

- 3.T.P.M. Procedures written and implemented to improve m/c up-time

- 4.Quality: Procedures written and introduced to improve standards

2000 – 2009

In 2004: Czech_Republic: Manufacturing FMCG in the mobile phone market the company required a dramatic increase in production. Using SMT technology to populate PCBs, 700 – 1000 personnel were employed working 3 shifts 24/7. Management felt that ‘Lean Application’ could improve the process, production output and profits… Present production 12,000 units per 24hrs. They required 22,000…

- 1.Time and Motion Study: highlighted where improvements could be made.

- 2.Training Given: Lean, 5S, WCM and continuous improvement philosophies.

- 3.A new factory layout drawn: “Single-Piece-Flow” line. 22,000/day achieved.

- 4.Process improvements generated: savings £1.2M… Growth potential $300M.

1990 – 1999

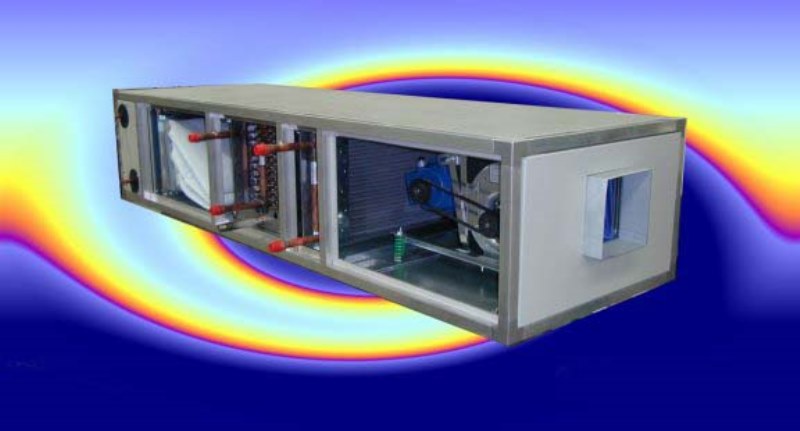

In 1999: Staffordshire: A company manufacturing high quality HVAC equipment felt that ‘Lean Application’ could improve their product and quality further and would give them the competitive edge in order to increase their business and profits…

- 1.Identify the opportunities

- 2.Implement lean process improvements

- 3.Standard Operation Work Procedures written

- 4.Quality procedures written and introduced to improve standards

Labour Time Improvement, Savings £45,000 – Inventory Cost Reduction £28,000 – Material Scrap Reduction £64,000 Customer Complaint Reduction £88,000…

Formation

Atherton_Management_Services: Based in Lancashire – We are Industrial Engineers, Business Improvement Consultants employing Work Study principles and techniques.

- Formed in the late 1980s:- ‘helping people in business – improve their business’ and have evolved over the years to be able to implement process improvements and generate cash and much more for our clients.

- In the beginning, using our engineering and work study background to complete many projects such as factory floor layouts, time and motion studies and factory re-location.

We Help People Identify Opportunities to Improve Processes and Reduce Costs

.

Atherton Management Services Ltd

.

Please Contact Us, We Are Happy To Help:

We’ve generated for our clients between £50k and £2.0M per project

For over 30 years we’ve designed and implemented “Business Improvement” Projects.

Please tell us your issues – tell us how you would like to improve your business.

Please Contact Us:- UK – 07300 788 486 – or by E-Mail